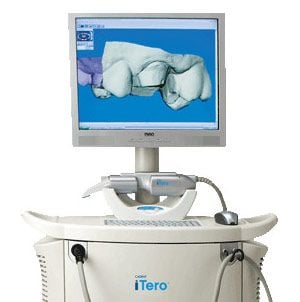

However, as we journey further into the technology-driven 21st century, this traditional methodology is being replaced with virtual models — made using small, handheld “wands” that employ a digital camera and some reflective dust.

The initial phase of restoration, preparing the tooth surface, remains virtually the same. First, any dental decay must be removed, and the remaining tooth must be shaped so that a crown or filling can be fitted properly. This will allow the tooth to be restored to its original shape, look, and function. Next, the area is lightly dusted with a reflective material (not a goopy impression material) so that multiple images of your tooth’s surface can be recorded with a small scanning wand. Later, the computer component is connected to the scanning wand and these separate images are combined into a computer-generated 3D image.

Once the image capture and prep work are satisfactory, your images are sent on to the lab for fabrication. This technique makes it possible to create a crown or a filling that can often be completed during a single office visit.